The blast furnace is the heart of the steel industry. It is a marvel of engineering that turns raw materials into the building blocks of modern society. Strong structural integrity and operating efficiency are required to withstand the tremendous heat of the furnace, which is necessary for processing. The blast furnace cooling system is critical in this scenario. A furnace’s longevity, efficiency, and safety depend on this component. In this blog, we will shed light on the blast furnace’s function, the cooling system’s importance, and the complex interplay of temperature, materials, and production that determines steel yield. We will also dive into the blast furnace stave cooling system.

The Role of Blast Furnace in Industry- What is it?

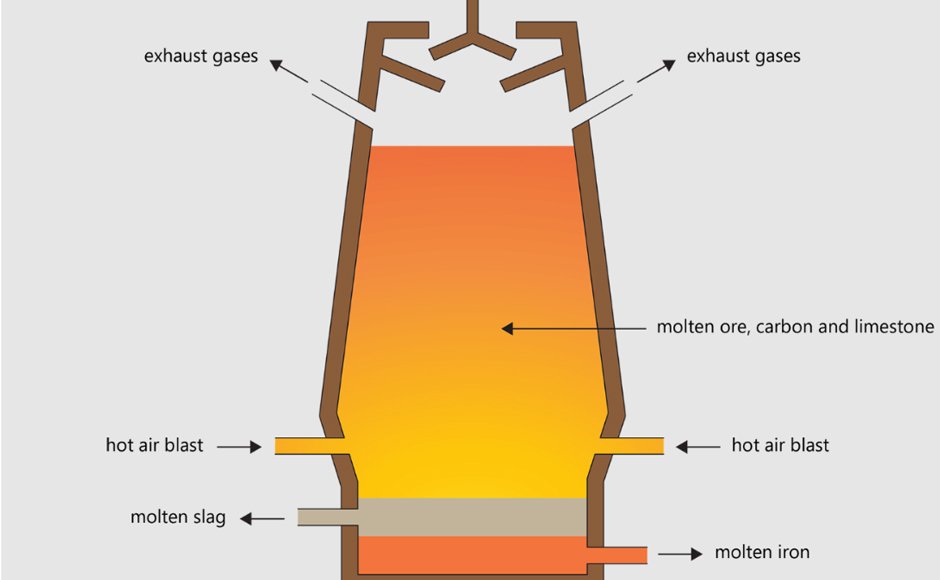

Beyond its physical form, the blast furnace serves as the engine that drives the steel industry. Its towering structure facilitates the processing of iron ore into liquid iron, a vital stage in the steelmaking process. It’s a complicated symphony of chemical reactions and temperature gradients inside a structure that can reach 45 meters tall. Every part and material matters at these severe temperatures. Maintaining forms is only one aspect of the structure’s integrity; another is ensuring everything works smoothly, safely, and efficiently. This is when the water cooling system in blast furnace comes into action. The worker goes unnoticed most of the time, quietly and effectively keeping everything stable and ensuring the furnace keeps working properly and consistently.

Blast Furnace Cooling System Explained

A system of water-cooling pipes within the blast furnace regulates the extremely high temperatures produced by the furnace, making it an essential component in producing iron and steel. This system of pipes allows water to flow through the furnace while it smelts, soaking up the heat. A series of heat exchangers and cooling towers bring the water temperature down to an ideal level for reducing iron ore in the furnace. Overheating can compromise structural integrity and make producing high-quality steel and iron difficult, but this method stops that from happening.

Why Implement a Cooling System in Blast Furnace

Stave cooling systems are a subset of blast furnace stave cooling systems that are designed to manage and control the temperature of the staves or walls of a blast furnace. Iron production generates tremendous heat, but this system’s complex parts reduce that heat. This optimizes operational efficiency by keeping the furnace from overheating and ensuring the machine’s structural integrity.

Improved Thermal Efficiency

A blast furnace’s thermal efficiency rests on its efficient plate coolers. It’s more than just cooling; it’s also about setting up an atmosphere where chemical reactions can occur optimally. This efficiency is more than just a statistic; it shows how well the furnace works, how much metal it can generate, and how good it is. This exemplifies the cooling system’s role in preserving the delicate equilibrium of heat, material, and reaction.

More production output

Keeping everything running at peak efficiency is crucial for reaching production goals. The water cooling system of the blast furnace ensures that the furnace stays within the specified temperature range, which allows for efficient and consistent iron production. To fulfill rising needs and take advantage of market opportunities, industries greatly benefit from this capacity to maintain uninterrupted production cycles free of overheating and structural difficulties.

Safety

Regarding blast furnaces, safety is still the number one priority. Iron production involves high temperatures and inherent dangers, so stringent safety precautions are required. To reduce the likelihood of damage from overheating and structural collapse, the water cooling system of the blast furnace is essential. With appropriate cooling systems, operators and maintenance workers can rest assured that they work in a safe and controlled environment.

Energy Efficiency

Industries serious about reducing their environmental effect and operational expenses must prioritize energy consumption management. The water cooling system of a blast furnace is essential for improving energy efficiency since it lowers the amount of energy required to keep the furnace at the correct temperature. With careful execution, this cooling procedure aids in conserving energy resources, perfectly aligning with sustainability goals. In addition, energy-efficient technology adoption is a proactive and forward-thinking alternative for businesses facing increasing demands for environmentally responsible operations.

Blast Furnace Cooling Staves- The types and The function

There are various types of blast furnace cooling staves in the production of iron and steel. The structural integrity and prevention of furnace overheating are ensured by cooling plates with internal water circulation channels. Heat is dispersed in hot furnace zones using ceramic staves, which are resistant to high temperatures. The exceptional heat conductivity of water-cooled copper staves allows for quickly removing heat from high-pressure regions. Slag-stopping plates aren’t designed to cool anything but aid in slag management, which means they can indirectly control temperature. Together, these various staves guarantee dependable and effective blast furnace functioning.

Conclusion

Industries producing iron can reap multiple advantages by installing a stave cooling system in their blast furnaces. There is no denying the favorable influence on operational performance, which includes optimizing heat efficiency, extending stave lifespan, increasing production output, and improving safety. Iron production in the future can be strong, eco-conscious, and safe if companies maximize their blast furnaces with a blast furnace cooling system and adhere to best practices.

Author:

Robert C. Green

The author is a metallurgy expert with a wealth of industry knowledge. With a passion for helping businesses optimize their processes and achieve excellence in metallurgical practices, they share valuable insights in their articles on metallurgy consulting.